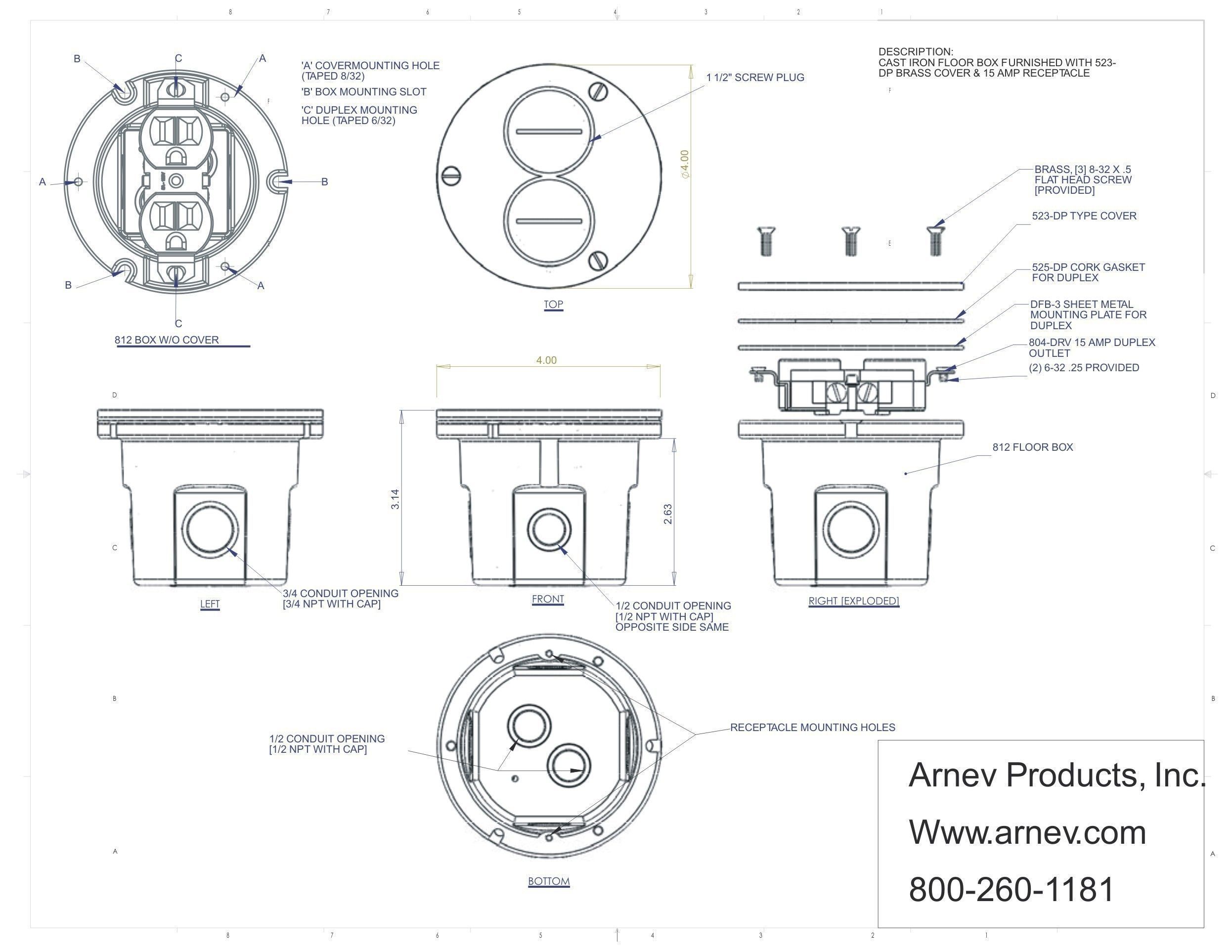

812-DFB SERIES

Installation Instructions

1. For wood floors

a. Using a 4” hole saw, cut the flooring to a depth equal to the thickness of the cast

flange and cover assembly being used on the floor box.

b. Center a 3.5” hole saw in the 4” opening and cut through all remaining layers of flooring.

This will create a lip for the flange of the box to rest on.

c. Remove the cover assembly and wiring device from the floor box.

d. Dropbox body into the opening and secure using #6 wood screws (not provided) through

the countersunk slots in the cast flange and into the underlying wood.

e. After wiring and installing electrical or communication devices to the floor box and ground

screw (if applicable), replace the cover plate assembly using #8/32 x ½” screws provided.

f. If an uneven cut was made into the flooring, goof rings (TCP-GR1) can be used in conjunction

with the original cover assembly or oversized covers (TCP series) can be used in place of the

original cover assembly.

g. For carpeted areas, use SCF-1 placed on top of the floor box (cover assembly removed first),

then insert the cover assembly into the carpet flange. Use 1.25” longer screws provided through

the cover assembly and that will affix to the floor box.

h. For tile applications, order part #812 (box body only) and a TCP-style cover. Follow steps a-d

above. After wiring in step e, install the mounting plate and gasket, then place the TCP style plate

on top of the floor and use #8/32 X ¾” screws provided.

2. For concrete floors

a. Not recommended for new construction as no concrete cap is provided and this is a nonadjustable box.

b. Core out 4 ¼” into concrete as deep as needed to accommodate the height of the box and the ability to

affix conduit from underneath.

c. Backfill concrete if necessary to close gaps in the floor.

d. Follow steps c-h above.

For Low voltage devices (CAT5-6, Tel, CTV, etc.) Click Here

This floor box is furnished with a Nickel Silver cover & a 15A Receptacle, and a Very heavy-duty cast iron box. Can be used for both Wood and Concrete floors. Additional covers that work with these boxes are the AP-TCP Series at 5-3/4 inch round in brass and aluminum or our AP-PFC series heavy plastic covers. Also, the AP-812-MKM double-hole saw is a convenient method for cutting the wood floor, as it's almost mistake-proof!

(Size: 4" x 3-1/8" 14.5 cu. in. interior)

Available 4" covers for this box above. Solid Brass, Aluminum, and some Nickel Silver

|

4'' Cover (1/8'' Thick) with

(2) 1-1/2'' Screw Plugs for

Duplex. Flush Mount.

|

Floor Box Cover for Concrete

Floors 4'' Cover (1/8'' Thick)

with (2) 1-1/2'' Screw Plugs

for Duplex

|

for Single Receptacles and

Concrete Floors 4'' Cover

(1/8'' Thick)

|

Cover for Concrete Floors

in Brass and Aluminum Dual

Hinged 4'' Cover

(1/4'' Thick) for Duplex

|

in Brass and Aluminum for

Concrete Floors Hinged 4''

Cover (1/4'' Thick) for Duplex

|

Box Cover Brass and

Aluminum for Concrete

Floors but for Decora

Receptacle

|

Box Cover Floor Box for

Telephone, for Concrete

Floors in Brass and Aluminum

|

|

812-DFB SERIES

Installation Instructions

1. For wood floors

a. Using a 4” hole saw, cut the flooring to a depth equal to the thickness of the cast

flange and cover assembly being used on the floor box.

b. Center a 3.5” hole saw in the 4” opening and cut through all remaining layers of flooring.

This will create a lip for the flange of the box to rest on.

c. Remove the cover assembly and wiring device from the floor box.

d. Dropbox body into the opening and secure using #6 wood screws (not provided) through

the countersunk slots in the cast flange and into the underlying wood.

e. After wiring and installing electrical or communication devices to the floor box and ground

screw (if applicable), replace the cover plate assembly using #8/32 x ½” screws provided.

f. If an uneven cut was made into the flooring, goof rings (TCP-GR1) can be used in conjunction

with the original cover assembly or oversized covers (TCP series) can be used in place of the

original cover assembly.

g. For carpeted areas, use SCF-1 placing on top of the floor box (cover assembly removed first),

then insert the cover assembly into the carpet flange. Use 1.25” longer screws provided through

the cover assembly and that will affix to the floor box.

h. For tile applications, order part #812 (box body only) and a TCP-style cover. Follow steps a-d

above. After wiring in step e, install the mounting plate and gasket, then place the TCP style plate

on top of the floor and use #8/32 X ¾” screws provided.

2. For concrete floors

a. Not recommended for new construction as no concrete cap is provided and this is a nonadjustable box.

b. Core out 4 ¼” into concrete as deep as needed to accommodate the height of the box and the ability to

affix conduit from underneath.

c. Backfill concrete if necessary to close gaps in the floor.

d. Follow steps c-h above.